Technology

Interaction is required

The contacting device

(adapter)

The tester hardware

The test PC with the corresponding software, which implements generic test methods

The actual test program, this is created individually for each assembly.

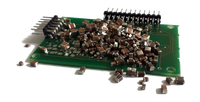

ICT (In Circuit Test)

In the in-circuit test, the assembled printed circuit board is tested for assembly errors.

Special technologies (guarding) allow the influence of surrounding components to be eliminated. In this way, test coverage of >90% can be achieved in many cases.

The test spectrum of the ICT includes:

- Short circuits, e.g. solder bridges)

- interruptions

- Resistors, capacitances, inductances

- Diodes (also reverse polarity detection), transistors

- Digital logic

- Analog ICs (OPV, comparators, linear regulators) and much more

ISP (In-System Programming)

For in-system programming there are different approaches, the selection is made either by the devices to be programmed or customer specification:

- Programming via debug or programming interfaces, directly via the tester hardware.

- Use of additional hardware for acceleration and parallelization

- Integration of manufacturer-specific programming devices

- Integration of universal programming devices

- Programming via JTAG by integration of hardware and software of the company Göpel

Depending on the devices to be programmed, up to 128 identical devices can be programmed simultaneously using the first two methods mentioned (utility programming). It is also possible to write variable data such as individual serial numbers.

BST (Boundary Scan test)

In the case of complex components such as microcontrollers, even tests for interruptions using in-circuit test methods can only be implemented to a very limited extent.

In addition, necessary test points are often omitted for space or EMC reasons.

The Boundary Scan Test (BST) was standardized in 1990 under IEEE 1149.1. Boundary scan can be used to perform electrical tests on assembled printed circuit boards. In addition to the core logic, boundary-scan-capable chips have an additional logic, the boundary-scan cell, with a test access port (TAP). Physical access in boundary-scan is via four interconnect lines.

The test spectrum of the BST includes:

- Short circuits, e.g. solder bridges)

- Interruptions, e.g. in jumpers.

- Digital logic

AST (Active Scan test)

The component test with active scan test is comparable in function to the Boundary Scan Test (BST) according to IEEE 1149.1. The AST can be used with microcontrollers that do not have internal BST logic.

Depending on the devivce, different technologies are used for the AST:

- Direct access via debug interfaces (e.g. BDM, SWD)

- Processing of test routines in RAM

- Processing of test routines in Flash

FCT (Functional Test)

In the functional test, individual functions of the module can be tested. These include, for example, power supply (switching controller) and communication buses (e.g. RS232, LIN and CAN).

In addition to pure testing for function, other functions can also be realized:

- Reading of software versions

- Reading and writing of parameters

- Serialization, writing of serial numbers

Adapter (contacting device)

For the various test procedures, the assembled PCB is contacted on special test points by means of spring-loaded needles.

The force required for this is generated mechanically on individual test stations by vacuum and when integrated into production lines. Contact can be made on one or both sides.

Demo video - how testing works